- Follows CCP/XCP standard communication protocols;

- Use .A2L files, which is compatible to the ASAP2 format;

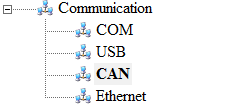

- Supports various communication media, including CAN, Ethernet, USB and RS232/SCI;

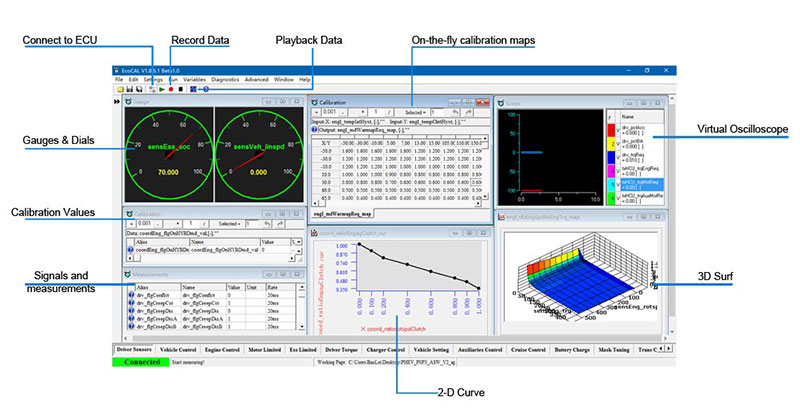

- Defines user calibration interfaces, like gauges, dials, plots, surfs, forms, and sheets, etc.;

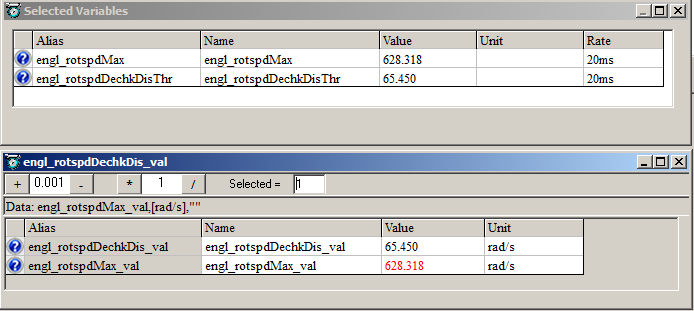

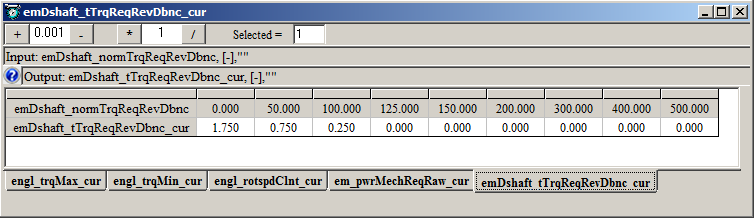

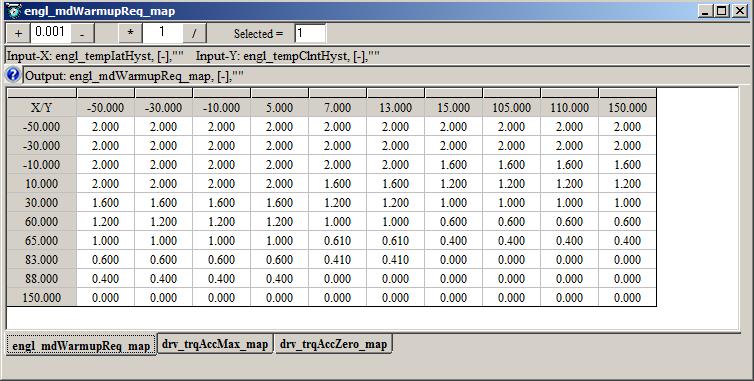

- Supports calibration values, curves, maps and bit-wise manipulating;

- On-the-fly calibration capability;

- Calibration data “burn to ECU” and “fetch from ECU”;

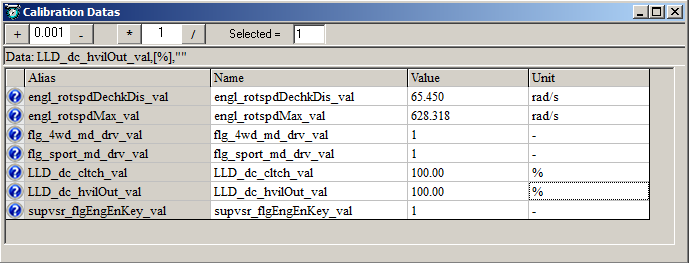

- Saves calibration data to files, manage the versions of calibration data sets;

- Calibration data management, including “copy”, “compare”, “view” (difference);

- Records data in CSV format and play-back in the Data Analyzer;

- Supports 080 standards, read diagnostic trouble codes (OTC), clear codes, and report failures.

EcoCAL supports various communication media including CAN, Ethernet, USS, RS 232/ and serial communication interface (Users can select the specific communication mode depending on the physical media.

Calibration data are stored in FLASH memory and have a copy in RAM. Users can change a calibration and hit “ENTER”, and the change takes effect immediately.

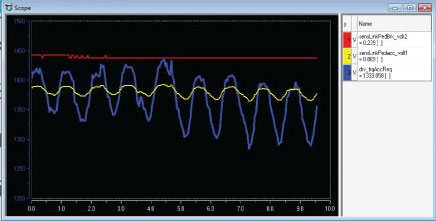

Virtual oscilloscope

The signals displayed on the screen are in the same for-mation as in the oscilloscope, with the valued traces and curves real time.

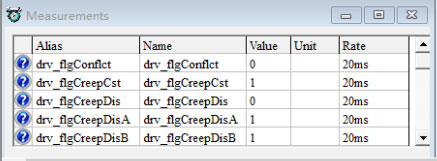

The signals and measurements are displayed digitally, which will be updated in real time.

Value View

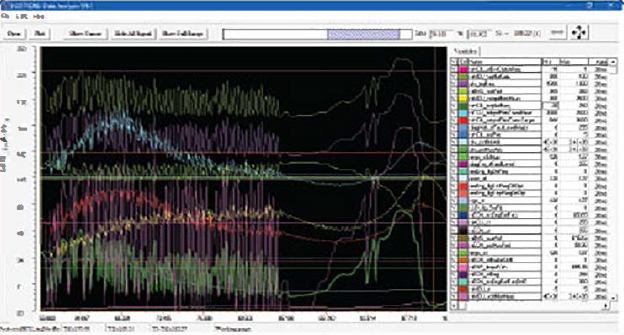

All measurements can be stored in the CSV files, which can be opened by the powerful Data Analyzer software, and MS Excel.

Replay the recorded data in the Analyzer, which is a tool in EcoCal. Users can select any signals to plot, zoom in&out and read the values at Cartesian coordinate system. Moreover, the users can edit the color, font, name, description, axis and ticks of the signal in the analyzing windows.

Users can read the OTC codes from the controller with the standard OBD protocols and find the failure easily.